Product Advantages

Now position:Home > Product Advantages

Product advantages

The process is purely and the products are burrs free.

THC's excellent mold structure has included the design of precise removal of waste, and no burrs will be generated during the processing process.

Looking at domestic and foreign counterparts, it is considered that the process of removing waste will leave burrs and flash as an inevitable problem. The use of frozen sand blasting to embritte the product and then apply a strong impact to solve this problem.

Looking at domestic and foreign counterparts, it is considered that the process of removing waste will leave burrs and flash as an inevitable problem, then using soon low temperature embrittlement and fast strong impact to solve this problem.

This will cause obvious and visible deformation of the product and invisible changes in physical properties and life attenuation.

And the customer must bear this unnecessary cost and loss.

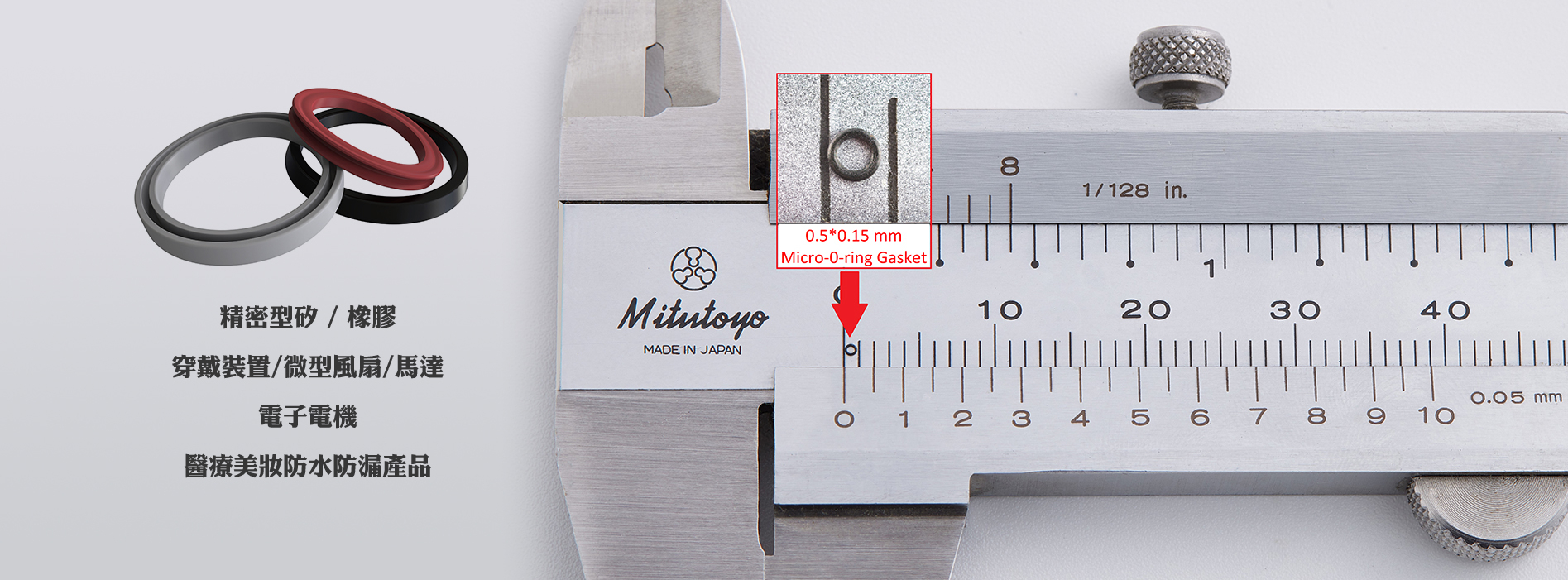

High-precision dimensional control and stable process

If the product deformation and burrs are judged to be unqualified under the projection measurement, it will not be able to meet the high-precision dimensional requirements.

Only a stable manufacturing process can effectively control the dimensions and reach the ultra-high level of burrs free, and pass the contour calculation and thickness detection of the CCD.

For the application of silicone rubber and rubber products, THC Enterprise Co., Ltd. has mature burr-free precision mold design and mass production technology, does not use ultra-low temperature freezing and strong impact to remove burrs, and does not affect the life and physical properties of silicone rubber and rubber; while reducing costs And improve the mechanical and design performance of the product, greatly reduce the risk of failure and effectively extend the life of the product. The reliability of its stable process has been verified and affirmed by many customers.

THC Enterprise has used AOI screening equipment in 2017 to strengthen the control of the burr-free process and the stability of product dimensions, eliminate visual uncertainties, and accurately detect surface defects such as mold contamination, air trips, flow marks, and comprehensively improve product reliability, and competitiveness with customers.

In response to the advancement of technology and the demand for automatic assembly, more and more customers require special surface processing.

In addition to the surface optimization treatment of the mold, THC Enterprise develops the corresponding raw material formula at the same time, It can achieve extremely low surface friction coefficient, superior product smoothness and anti-static function, it is the best option for automatic assembly equipment.

In response to the demand for full coating on the surface of the product, THC Enterprise has completed a variety of material and coating tests, there are rich and complete processes for customers choose from, it can completely cover the capillary of the product to prevent the precipitation of heterogeneity,

Protect the product and block the influence of organic solvents, inorganic reagents, acid and alkaline solutions, and prolong the effective life of the product.